Tel: 01763 262333

Ultra-micropore Analysis

The

term

ultra-micropore,

sometimes

also

super-micropore,

has

become

commonly

used

to

describe

pores

smaller

than

1nm

diameter

(micropores

in

general

are

those

smaller

than

2nm

diameter).

Ultra-micropores

are

commonly

present

in

materials

such

as

activated

carbons,

carbon

nanotubes,

zeolites,

metal

organic

frameworks

(MOFs),

zeolitic

imidazolate

frameworks

(ZIFs)

and

covalent

organic

frameworks

(COFs).

Their

presence

is

often

fundamental

to

applications

and

can

be

extremely

influential

to

capacity,

activity,

adsorption

behaviour,

functionality

and

accessibility.

Typical

applications

include

battery

materials,

adsorbents

and

filters,

catalysts

and

gas

storage

/

sequestration

materials.

Whilst

micropores

are

frequently

required,

their

specific

size

and

volume

must

be

tightly

controlled

in

order

to

maximise

performance

characteristics.

Micropores of the wrong size may cause poor performance or product failure due to low capacity, inaccessibility or pore blocking.

Using

the

most

recent,

state-of-the-art

instrumentation

it

is

possible

to

fully

characterise

micropores

for

their

volume,

surface

area

and

size

distribution.

Together

these

describe

the

porous

nature

of

a

material

and

allow

for

the

relationships

with

material

selection

and

performance

to

be

established.

It

is

then

possible

to

define

the

specific

porous

characteristics

required

from

material

selection,

design,

production

or

regeneration.

Key Applications

Micropore size distribution, volume and pore area for:

Adsorbent capacity, accessibility and retention

Sequestration capacity, accessibility and retention

Gas storage capacity, accessibility and retention

Catalyst efficiency and activity

Battery electrode efficiency, activity and charge / discharge ability

Filter efficiency and efficacy

Determination of regeneration conditions and efficiency

Investigations of atypical performance: effects of low capacity and retention

Investigations of product failure: pore blocking

Identification of optimum characteristics and selection of materials

Determination of production and fabrication conditions

At

MCA

Services

we

use

the

latest,

state-of-the-art

Micromeritics

3Flex

instrument

for

micropore

analysis

which

applies

the

volumetric

method

for

the

measurement

of

adsorption

isotherms.

Nitrogen

is

most

commonly

used

as

the

adsorbate

with

excellent

results

and

the

capability

of

extending

analyses

to

measure

data

in

the

mesopore

region.

Combined

micropore

and

mesopore

analyses

are,

therefore,

possible

in

a

single

analysis

and

extensive

data

reduction

and

reporting

methods

can

be

employed

to

characterise

each.

With

some

sample

materials,

when

unfavourable

interactions

between

nitrogen

and

the

sample

surface

are

area

likely,

it

is

preferable

to

select

an

alternative

adsorbate.

In

such

cases argon adsorption is a suitable analytical method.

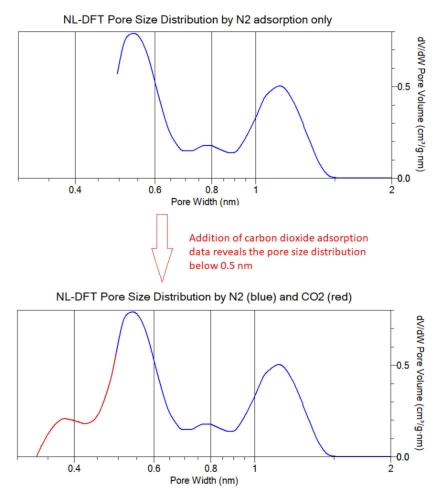

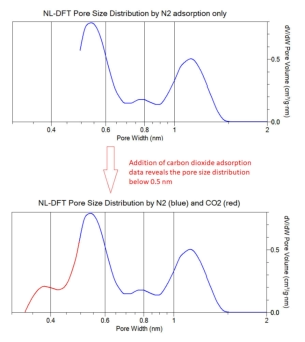

However,

when

samples

contain

ultra-micropores

smaller

than

approximately

0.5nm,

nitrogen

and

argon

adsorption

become

problematic

due

to

slow

or

incomplete

accessibility

to

the

smallest

pores

at

the

analysis

temperature.

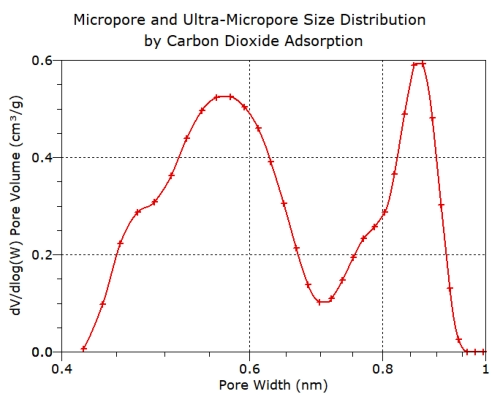

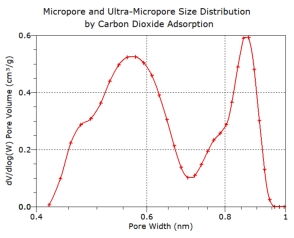

In

such

cases,

CO

2

adsorption

is

recommended

as

this

can

be

used

to

characterise

pores

as

in

the

range

0.32

-

1.0

nm

diameter

(depending

on

analysis

temperature).

It

is

also

possible

to

combine

CO

2

adsorption isotherms with those of N

2

or Ar to obtain a complete pore characterisation throughout the micropore and mesopore ranges.

Analytical Options and Highlights

Nitrogen adsorption isotherms for micropore and mesopore characterisation

Argon adsorption isotherms for micropore and mesopore characterisation

Carbon dioxide adsorption isotherms for ultra- micropore characterisation

Nitrogen adsorption at 77K

Argon adsorption at 77K or 87K

Carbon dioxide adsorption at 258 – 298 K

Micropore size distribution data (graphical and numerical)

Micropore volume and surface area data (graphical and numerical)

Combination of CO

2

and N

2

or Ar data for complete characterisation

Data reduction by DFT and NL-DFT methods

Comprehensive degassing options

The

Micromeritics

3Flex

is

an

extremely

powerful

instrument

with

cutting

edge

technology

and

a

wealth

of

information

can

be

obtained

from

comprehensive

data

reduction

software.

Combined

with

our

decades

of

experience

the

maximum

information

about

your

samples

can

be

obtained

from

a

single

analysis.

At

MCA

Services

we

are

always

happy

to

advise

the

best

analytical

option

for

your

particular

samples,

applications

and

requirements.

We

also

routinely

assist

in

data

interpretation:

selecting

the

most

pertinent

reporting

data

and

relating

porous

characteristics

to

your specific materials and requirements.

Ultra-micropore Analysis

The

term

ultra-micropore,

sometimes

also

super-micropore,

has

become

commonly

used

to

describe

pores

smaller

than

1nm

diameter

(micropores

in

general

are

those

smaller

than

2nm

diameter).

Ultra-micropores

are

commonly

present

in

materials

such

as

activated

carbons,

carbon

nanotubes,

zeolites,

metal

organic

frameworks

(MOFs),

zeolitic

imidazolate

frameworks

(ZIFs)

and

covalent

organic

frameworks

(COFs).

Their

presence

is

often

fundamental

to

applications

and

can

be

extremely

influential

to

capacity,

activity,

adsorption

behaviour,

functionality

and

accessibility.

Typical

applications

include

battery

materials,

adsorbents

and

filters,

catalysts

and

gas

storage

/

sequestration

materials.

Whilst

micropores

are

frequently

required,

their

specific

size

and

volume

must

be

tightly

controlled

in

order

to

maximise

performance

characteristics.

Micropores

of

the

wrong

size

may

cause

poor

performance

or

product

failure

due

to

low

capacity, inaccessibility or pore blocking.

Using

the

most

recent,

state-of-the-art

instrumentation

it

is

possible

to

fully

characterise

micropores

for

their

volume,

surface

area

and

size

distribution.

Together

these

describe

the

porous

nature

of

a

material

and

allow

for

the

relationships

with

material

selection

and

performance

to

be

established.

It

is

then

possible

to

define

the

specific

porous

characteristics

required

from

material selection, design, production or regeneration.

Key Applications

Micropore size distribution, volume and pore area for:

Adsorbent capacity, accessibility and retention

Sequestration capacity, accessibility and retention

Gas storage capacity, accessibility and retention

Catalyst efficiency and activity

Battery efficiency, activity and charge / discharge ability

Filter efficiency and efficacy

Determination of regeneration conditions and efficiency

Investigations of atypical performance:

effects of low capacity and retention

Investigations of product failure: pore blocking

Identification of optimum characteristics and materials selection

Determination of production and fabrication conditions

At

MCA

Services

we

use

the

latest,

state-of-the-art

Micromeritics

3Flex

instrument

for

micropore

analysis

which

applies

the

volumetric

method

for

the

measurement

of

adsorption

isotherms.

Nitrogen

is

most

commonly

used

as

the

adsorbate

with

excellent

results

and

the

capability

of

extending

analyses

to

measure

data

in

the

mesopore

region.

Combined

micropore

and

mesopore

analyses

are,

therefore,

possible

in

a

single

analysis

and

extensive

data

reduction

and

reporting

methods

can

be

employed

to

characterise

each.

With

some

sample

materials,

when

unfavourable

interactions

between

nitrogen

and

the

sample

surface

are

area

likely,

it

is

preferable

to

select

an

alternative

adsorbate.

In

such

cases

argon

adsorption

is

a

suitable

analytical

method.

However,

when

samples

contain

ultra-micropores

smaller

than

approximately

0.5nm,

nitrogen

and

argon

adsorption

become

problematic

due

to

slow

or

incomplete

accessibility

to

the

smallest

pores

at

the

analysis

temperature.

In

such

cases,

CO2

adsorption

is

recommended

as

this

can

be

used

to

characterise

pores

as

in

the

range

0.32

-

1.0

nm

diameter

(depending

on

analysis

temperature).

It

is

also

possible

to

combine

CO2

adsorption

isotherms

with

those

of

N2

or

Ar

to

obtain

a

complete

pore

characterisation

throughout

the

micropore

and

mesopore

ranges.

Analytical Options and Highlights

Nitrogen adsorption for micropore and mesopore characterisation

Argon adsorption for micropore and mesopore characterisation

Carbon dioxide isotherms for ultra- micropore characterisation

Nitrogen adsorption at 77K

Argon adsorption at 77K or 87K

Carbon dioxide adsorption at 258 – 298 K

Micropore size distribution data (graphical and numerical)

Micropore volume and surface area data

Combination of CO

2

and N

2

or Ar data

Data reduction by DFT and NL-DFT methods

Comprehens

ive degassing options

The

Micromeritics

3Flex

is

an

extremely

powerful

instrument

with

cutting

edge

technology

and

a

wealth

of

information

can

be

obtained

from

comprehensive

data

reduction

software.

Combined

with

our

decades

of

experience

the

maximum

information

about

your

samples

can

be

obtained

from

a

single

analysis.

At

MCA

Services

we

are

always

happy

to

advise

the

best

analytical

option

for

your

particular

samples,

applications

and

requirements.

We

also

routinely

assist

in

data

interpretation:

selecting

the

most

pertinent

reporting

data

and

relating

porous

characteristics

to

your specific materials and requirements.