Physical Characterisation of Catalysts

Key Techniques

Micropore Analysis: pore size, area and volume in the micropore range

Micropore Analysis: choice of adsorbate for ultra-micropore characterisation

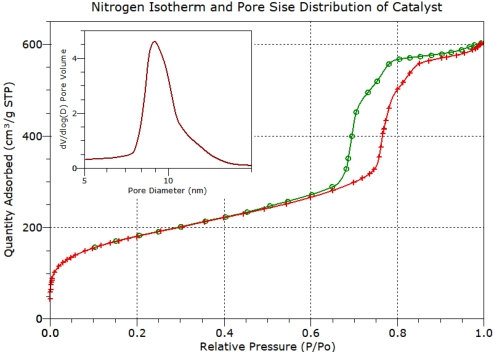

Gas Adsorption: pore size, area and volume in the mesopore range

Gas Adsorption: BET Surface Area

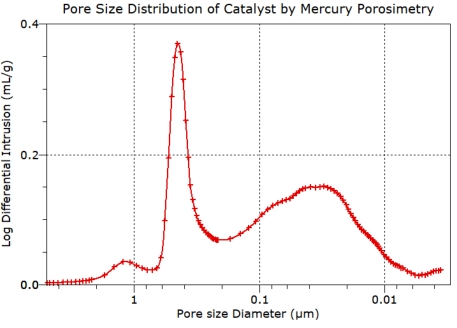

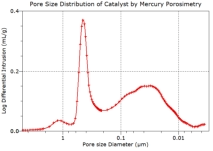

Mercury Porosimetry: pore size, area and volume in meso & macropore ranges

Mercury Intrusion / Extrusion Porosimetry: cavity to throat size

Chemisorption: active metal surface area and dispersion measurement

Permeability and Tortuosity: measurement by mercury intrusion porosimetry

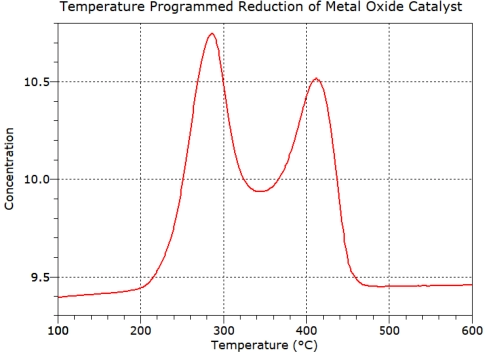

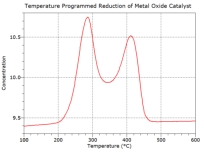

Temperature Programmed Methods: reduction, oxidation & desorption

Density Measurement: absolute density, bulk density and skeletal density

MCA

Services

offers

a

complete

suite

of

techniques

for

the

physical

characterisation

of

catalyst

systems.

The

combination

of

mercury

porosimetry

and

gas

adsorption

provides

characterisation

throughout

the

pore

size

range,

from

ultra-micropores

through

to

macro-pores

with

a

maximum

size

of

~

650

µm.

Mercury

porosimetry

can

be

extended

to

consider

extrusion

analysis

for

consideration

of

pore

geometry

as well as permeability and tortuosity determination.

Most

gas

adsorption

options

also

include

the

calculation

of

BET

surface

area

as

standard.

Whilst

nitrogen

adsorption

is

the

most

commonly

applied

technique,

alternatives

are

available

for

more

specialised

analyses.

For

example

carbon

dioxide

for

ultra-micropores

with

the

capability

of

combination

with

nitrogen

adsorption

to

complete

a

single,

harmonious,

pore

size

distribution.

Argon

adsorption

is

available

for

micro-porous

materials

proving

problematic

for

nitrogen

adsorption,

for

example

those

with

charged

surface

species

such

as

zeolites

and

organic frameworks.

Chemisorption

(chemical

adsorption)

is

routinely

applied

to

the

analysis

of

active

metal

constituents

to

determine

their

availability

for

a

desired

catalytic

reaction.

Active

metal

dispersion,

surface

area

and

crystallite

size

are

commonly

applied

and

at

MCA

Services

we

offer

measurements

using

both

static

and

dynamic

methods.

Hydrogen

and

carbon

monoxide

sorption

represent

the

most

common

approach

but

we

also

offer

more

specialised

options,

for

example

nitrous

oxide

and

ammonia

to

ensure

that

the

majority

of

active

metals

and

loadings

can

be

analysed

with

confidence.

Alongside

chemisorption,

our

Temperature

Programmed

options

provide

analyses

for

reduction,

oxidation

and

desorption,

completing

the

characterisation

and

understanding

of

active

constituents.

All

are

applicable

to

new

and

spent

catalyst

materials

and

are

particularly

useful

when

considering

the

development or assessment of a system, its performance and its regeneration.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

range

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application

in

a

battery

system.

Combined

with

state-of-

the-art

instrumentation

and

software,

offering

flexible

and

extensive

reporting

options,

we

help

to

maximise

the

amount

of

high

quality

data

describing

sample

materials.

The

significance

and

influence

of

the

porous

nature

of

catalyst

systems

with

respect

to

their

functionality,

performance

and

efficiency

is

well

known,

as

is

the

understanding

of

the

physico-chemical

properties

of

the

active

constituents.

Characterisation

of

the

porous

nature

of

catalysts

can

be

applied

to

the

active

constituents,

support

materials

or

the

finished

system.

Understanding

the

porous

and

active

nature

of

catalysts

is

vital to both un-used and spent materials and also to considering degradation and the regeneration process.

Tel: 01763 262333

Key Techniques.

Micropore Analysis: pore size, area and volume determination

in the micropore range.

Micropore Analysis: wide choice of adsorbate gases for ultra-

micropore characterisation.

Gas Adsorption: pore size, area and volume determination in

the mesopore range.

Gas Adsorption: BET Surface Area.

Mercury Porosimetry: pore size, area and volume

determination in meso & macropore ranges.

Mercury Intrusion / Extrusion Porosimetry: cavity to throat

size determination.

Chemisorption: active metal surface area and dispersion

measurement – static and dynamic methods.

Permeability and Tortuosity: measurement by mercury

intrusion porosimetry.

Temperature Programmed Methods: reduction, oxidation,

adsorption & desorption.

Density Measurement: absolute density, bulk (envelope)

density and skeletal density

MCA

Services

offers

a

complete

suite

of

techniques

for

the

physical

characterisation

of

catalyst

systems.

The

combination

of

mercury

porosimetry

and

gas

adsorption

provides

characterisation

throughout

the

pore

size

range,

from

ultra-

micropores

through

to

macro-pores

with

a

maximum

size

of

~

650

µm.

Mercury

porosimetry

can

be

extended

to

consider

extrusion

analysis

for

consideration

of

pore

geometry

as

well

as

permeability and tortuosity determination.

Most

gas

adsorption

options

also

include

the

calculation

of

BET

surface

area

as

standard.

Whilst

nitrogen

adsorption

is

the

most

commonly

applied

technique,

alternatives

are

available

for

more

specialised

analyses.

For

example

carbon

dioxide

for

ultra-

micropores

with

the

capability

of

combination

with

nitrogen

adsorption

to

complete

a

single,

harmonious,

pore

size

distribution.

Argon

adsorption

is

available

for

micro-porous

materials

proving

problematic

for

nitrogen

adsorption,

for

example

those

with

charged

surface

species

such

as

zeolites

and

organic frameworks.

Chemisorption

(chemical

adsorption)

is

routinely

applied

to

the

analysis

of

active

metal

constituents

to

determine

their

availability

for

a

desired

catalytic

reaction.

Active

metal

dispersion,

surface

area

and

crystallite

size

are

commonly

applied

and

at

MCA

Services

we

offer

measurements

using

both

static

and

dynamic

methods.

Hydrogen

and

carbon

monoxide

sorption

represent

the

most

common

approach

but

we

also

offer

more

specialised

options,

for

example

nitrous

oxide

and

ammonia

to

ensure

that

the

majority

of

active

metals

and

loadings

can

be

analysed

with

confidence.

Alongside

chemisorption,

our

Temperature

Programmed

options

provide

analyses

for

reduction,

oxidation

and

desorption,

completing

the

characterisation

and

understanding

of

active

constituents.

All

are

applicable

to

new

and

spent

catalyst

materials

and

are

particularly

useful

when

considering

the

development

or

assessment of a system, its performance and its regeneration.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

range

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application

in

a

battery

system.

Combined

with

state-of-the-art

instrumentation

and

software,

offering

flexible

and

extensive

reporting

options,

we

help

to

maximise

the

amount

of

high

quality

data

describing

sample materials.

Physical Characterisation of Catalysts

The

significance

and

influence

of

the

porous

nature

of

catalyst

systems

with

respect

to

their

functionality,

performance

and

efficiency

is

well

known,

as

is

the

understanding

of

the

physico-

chemical

properties

of

the

active

constituents.

Characterisation

of

the

porous

nature

of

catalysts

can

be

applied

to

the

active

constituents,

support

materials

or

the

finished

system.

Understanding

the

porous

and

active

nature

of

catalysts

is

vital

to

both

un-used

and

spent

materials

and

also

to

considering

degradation and the regeneration process.