Tel: 01763 262333

Physical Characterisation of Ceramics and Filter Media

The

porosity

of

ceramics

and

filter

media

is

often

inextricably

linked

to

their

performance

in

a

wide

range

of

applications.

When

selecting,

assessing

or

producing

ceramics

and

filter

media

it

is

necessary

to

consider

the

required

porous

characteristics

with

respect

to

the

intended

application.

Changes

in

porosity

also

need

to

be

considered

during

product

use,

especially

with

regard

to

capacity

thresholds,

pore

blocking

or

fouling

and

product

regeneration.

The

porous

nature

of

raw

material

powders,

together

with

manufacturing

conditions,

often

dictate

the

ultimate

pore size and volume of a finished product, and therefore its efficacy.

Key Applications

Determination of pore size and volume

Determination of absolute porosity

Selection and control of raw material constituents

Formulation and fabrication process control

Identification of optimum fabrication conditions

Selection of materials for specific applications

Monitoring of products for efficacy during use

Investigation product failure and performance issues

Investigating product regeneration

Application to filtration of gaseous environments

Application to fluid environments and water treatment

Ceramics

and

filter

media

are

applied

to

a

very

broad

range

of

applications

and

are

intended

for

exposure

to

a

diverse

range

of

operating

conditions

and

interacting

species,

from

gaseous

molecules

to

fluid

and

water

contaminants.

Requirements

of

pore

size,

pore

volume

and

specific

surface

area

therefore

cover

a

wide

range

are

usually

very

demanding

with

respect

to

the

absolute

values.

At

MCA

Services

we

offer

a

complete

suite

of

analytical

techniques

which

allows

for

the

complete

characterisation

of

porosity

throughout

the

ranges

of

ultra-micropores

(<

1nm

diameter)

through

to

macro-pores

(up

to

650

µm).

When

the

ceramic

or

filter

media

is

doped

with

a

chemically

active

metallic

component,

chemisorption

options

become

particularly

useful.

Chemisorption

provides

the

means

of

analysing

the

active

component

alone

for

its

surface

area,

crystallite size and, importantly, availability via its dispersion.

Key Applications

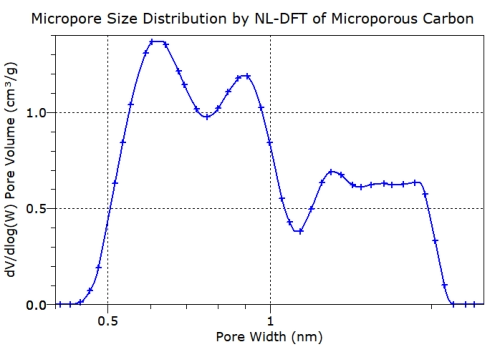

Gas Adsorption

Ultra-micropore analysis (< 1.0 nm)

Micropore analysis (< 2.0 nm)

Mesopore analysis (2 – 50 nm)

Pore volume measurement

Pore size distribution measurement

Specific surface area (BET) measurement

Specific probe gases available

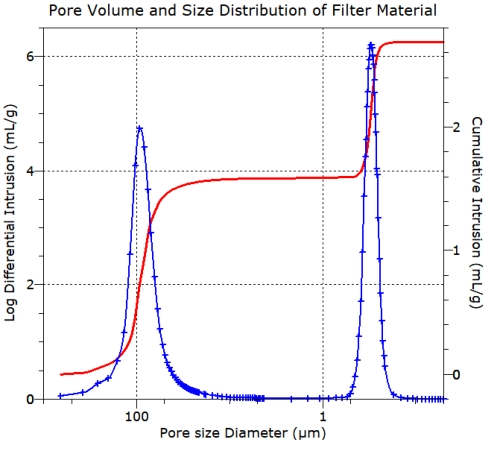

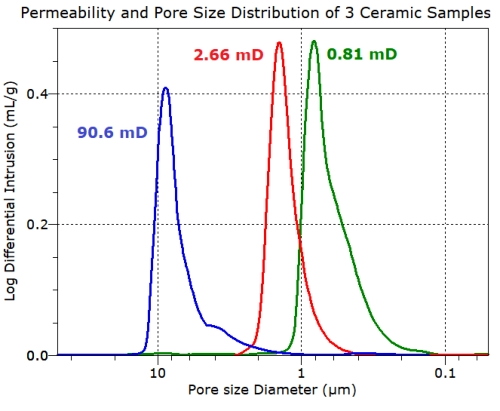

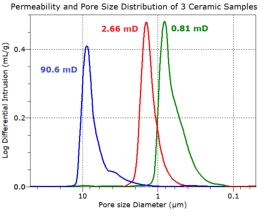

Mercury Porosimetry

Mercury intrusion and extrusion options

Mesopore & Macropore analysis (3.5 nm – 650 µm)

Pore volume measurement

Pore size distribution measurement

Absolute porosity, bulk density and skeletal density

Permeability and tortuosity measurement

Cavity to throat size measurement

Helium Pycnometry

Absolute density measurement

Chemisorption and Temperature Programmed Analysis

Application to active metal doped media

Active component dispersion and surface area

Reduction, oxidation and desorption temperature profiles

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

range

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application

in

a

battery

system.

Combined

with

state-of-the-art

instrumentation

and

software, offering flexible and extensive reporting options, we help to maximise the amount of high quality data describing sample materials.

Physical Characterisation of Ceramics and Filter Media

The

porosity

of

ceramics

and

filter

media

is

often

inextricably

linked

to

their

performance

in

a

wide

range

of

applications.

When

selecting,

assessing

or

producing

ceramics

and

filter

media

it

is

necessary

to

consider

the

required

porous

characteristics

with

respect

to

the

intended

application.

Changes

in

porosity

also

need

to

be

considered

during

product

use,

especially

with

regard

to

capacity

thresholds,

pore

blocking

or

fouling

and

product

regeneration.

The

porous

nature

of

raw

material

powders,

together

with

manufacturing

conditions,

often

dictate

the

ultimate

pore

size

and

volume

of

a

finished

product,

and

therefore

its

efficacy.

Key Applications

Determination of pore size and volume

Determination of absolute porosity

Selection and control of raw material constituents

Formulation and fabrication process control

Identification of optimum fabrication conditions

Selection of materials for specific applications

Monitoring of products for efficacy during use

Investigation product failure and performance issues

Investigating product regeneration

Application to filtration of gaseous environments

Application to fluid environments and water treatment

Ceramics and filter media are applied to a very broad range of

applications and are intended for exposure to a diverse range of

operating conditions and interacting species, from gaseous

molecules to fluid and water contaminants. Requirements of pore

size, pore volume and specific surface area therefore cover a wide

range are usually very demanding with respect to the absolute

values. At MCA Services we offer a complete suite of analytical

techniques which allows for the complete characterisation of

porosity throughout the ranges of ultra-micropores (< 1nm

diameter) through to macro-pores (upto 650 µm). When the

ceramic or filter media is doped with a chemically active metallic

component, chemisorption options become particularly useful.

Chemisorption provides the means of analysing the active

component alone for its surface area, crystallite size and,

importantly, availability via its dispersion.

Key Applications

Gas Adsorption

Ultra-micropore analysis (< 1.0 nm)

Micropore analysis (< 2.0 nm)

Mesopore analysis (2 – 50 nm)

Pore volume measurement

Pore size distribution measurement

Specific surface area (BET) measurement

Specific probe gases available

Mercury Porosimetry

Mercury intrusion and extrusion options

Mesopore & Macropore analysis (3.5 nm – 650 µm)

Pore volume measurement

Pore size distribution measurement

Absolute porosity, bulk density and skeletal density

Permeability and tortuosity measurement

Cavity to throat size measurement

Helium Pycnometry

Absolute density measurement

Chemisorption and Temperature Programmed Analysis

Application to active metal doped media

Active component dispersion and surface area

Reduction, oxidation and desorption temperature profiles

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

range

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application

in

a

battery

system.

Combined

with

state-of-the-art

instrumentation

and

software,

offering

flexible

and

extensive

reporting

options,

we

help

to

maximise

the

amount

of

high

quality

data

describing

sample

materials.