Mesopores and Small Macropores

Gas adsorption for the pore size range 2 - ~300 nm*

Specific (BET) Surface Area (numerical value and graphical plot)

Pore Volume (numerical value and graphical plot)

Pore Area (numerical value and graphical plot)

Average Pore Size (numerical values)

Pore Size Distribution (numerical value and graphical plot)

Assessment of Pore Geometry

Micropore Volume

Choice of Adsorbates

* Depending on nature of sample

Tel: 01763 262333

Porosimetry Analysis

Porosimetry

covers

a

range

of

analytical

techniques

used

for

understanding

and

characterising

the

porous

nature

of

materials.

Porosity

often

has

profound affects on the behaviour of materials and influences many aspects of their selection, fabrication, application, performance and life-cycle.

Porosity

is

a

broad

term

which

encompasses

physical

characteristics

such

as

pore

volume,

pore

surface

area,

pore

size

distribution,

specific

surface

area,

absolute

porosity

and

pore

geometry.

It

also

has

direct

relationships

with

the

various

measures

of

sample

density,

gas

and

fluid

permeability

and

chemical

activity.

All

of

these

aspects

of

porosity

can

be

characterised

at

MCA

Services

using

a

range

of

state-of-the-art

analytical

instruments.

Our

expertise

in

the

application

of

analyses

and

interpretation

means

that

the

most

pertinent

data

is

presented

and

related

directly to specific materials and applications.

Porosity

is

commonly

considered

as

being

present

within

a

solid

material

but

it

is

also

present

in

the

void

spaces

of

a

powder

material.

Such

inter-

particulate

porosity

is

determined

by

the

particle

size

and

shape

of

the

powder

grains,

essentially

reflecting

the

packing

properties

of

powder

particles.

Understanding

inter-particulate

porosity

becomes

very

significant

when

a

powder

is

used

in

the

fabrication

of

a

solid

article.

Combined

with the process conditions, such as compression, binder composition and firing temperature it determines the porosity within the finished article.

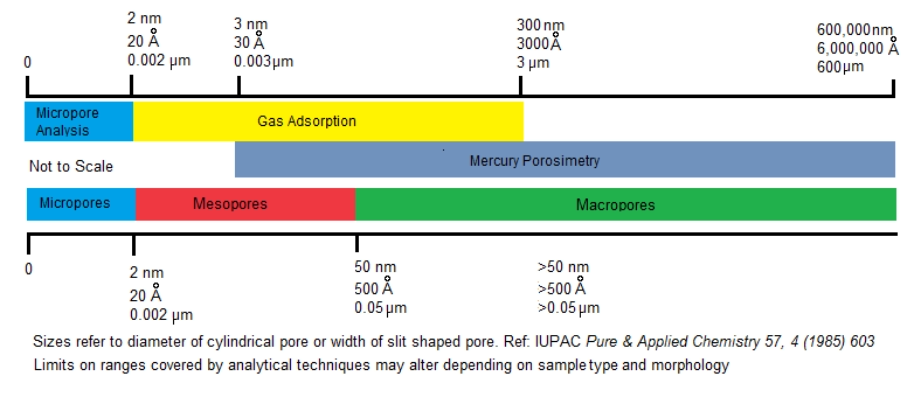

Pore

sizes

can

be

divided

into

three

ranges:

Micropores

(<

2nm),

Mesopores

(2

–

50

nm)

and

Macropores

(>

50nm),

the

sizes

refer

to

the

diameter

of

a

cylindrical

pore

or

the

width

of

a

slit-shaped

pore

according

to

IUPAC

definitions.

Micro-pores

are

sometimes

further

divided

to

include

super-micropores,

or

ultra-micropores

which

are

smaller

than

1

nm.

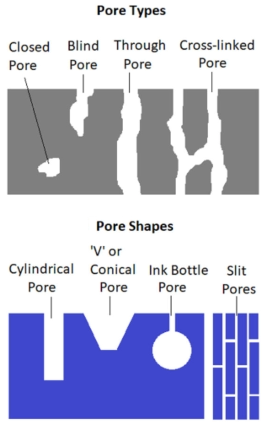

Pore

geometry, which includes types and shapes of pores should also be considered.

There

is

no

single

technique

that

can

be

used

to

determine

porous

characteristics

throughout

the

ranges

of

pore

sizes.

Therefore,

it

is

usually

necessary

to

select

the

most

appropriate

technique

or

combination

of

techniques

for

a

given

sample

and

application.

At

MCA

Services

we

have

decades

of

experience

in

this

and

are

always

happy

to

provide

our

thoughts

on

this

selection.

Mesopores and Macropores

Mercury porosimetry

for the pore size range 3.5 nm – 650 µm*

Pore Volume (numerical value and graphical plot)

Pore Area (numerical value and graphical plot)

Average Pore Size (numerical values)

Pore Size Distribution (numerical value and graphical plot)

Bulk and Skeletal Density

Absolute Porosity (% volume)

Permeability

Pore Tortuosity

* Depending on nature of sample

Micropores

Gas adsorption for the pore size range 0.3 – 2 nm

Pore Volume (numerical value and graphical plot)

Pore Area (numerical value and graphical plot)

Average Pore Size (numerical values)

Nitrogen Adsorption (pores 0.45 – 2 nm)

Nitrogen Adsorption Full Isotherm (pores 0.45 - ~300nm*)

Carbon Dioxide Adsorption (pores 0.3 – 0.45 nm)

Combined CO

2

and N

2

Isotherms (pores 0.3 - ~300nm*)

Choice of Adsorbates (N

2

, CO

2

, Ar, H

2

, O

2

)

More

information

can

be

found

on

our

specific

Analytical

Options

pages

and

at

MCA

Services

we

are

always

happy

to

discuss

particular

requirements, sample types and applications to determine the more appropriate techniques for the characterisation of your samples.

MCA Services

01763 262333

More

information

can

be

found

on

our

specific

Analytical

Options

pages

and

at

MCA

Services

we

are

always

happy

to

discuss

particular

requirements,

sample

types

and

applications

to

determine

the

more

appropriate

techniques

for

the

characterisation of your samples.

There

is

no

single

technique

that

can

be

used

to

determine

porous

characteristics

throughout

the

ranges

of

pore

sizes.

Therefore,

it

is

usually

necessary

to

select

the

most

appropriate

technique

or

combination

of

techniques

for

a

given

sample

and

application.

At

MCA

Services

we

have

decades

of

experience

in

this

and

are

always

happy

to

provide

our

thoughts

on

this

selection.

Pore

sizes

can

be

divided

into

three

ranges:

Micropores

(<

2nm),

Mesopores

(2

–

50

nm)

and

Macropores

(>

50nm),

the

sizes

refer

to

the

diameter

of

a

cylindrical

pore

or

the

width

of

a

slit-shaped

pore

according

to

IUPAC

definitions.

Micro-pores

are

sometimes

further

divided

to

include

super-micropores,

or

ultra-micropores

which

are

smaller

than

1

nm.

Pore

geometry,

which

includes

types

and

shapes

of

pores should also be considered.

Porosimetry Analysis

Porosimetry

covers

a

range

of

analytical

techniques

used

for

understanding

and

characterising

the

porous

nature

of

materials.

Porosity

often

has

profound

affects

on

the

behaviour

of

materials

and

influences

many

aspects

of

their

selection,

fabrication,

application, performance and life-cycle.

Porosity

is

a

broad

term

which

encompasses

physical

characteristics

such

as

pore

volume,

pore

surface

area,

pore

size

distribution,

specific

surface

area,

absolute

porosity

and

pore

geometry.

It

also

has

direct

relationships

with

the

various

measures

of

sample

density,

gas

and

fluid

permeability

and

chemical

activity.

All

of

these

aspects

of

porosity

can

be

characterised

at

MCA

Services

using

a

range

of

state-of-the-art

analytical

instruments.

Our

expertise

in

the

application

of

analyses

and

interpretation

means

that

the

most

pertinent

data

is

presented

and

related

directly

to

specific

materials

and

applications.

Porosity

is

commonly

considered

as

being

present

within

a

solid

material

but

it

is

also

present

in

the

void

spaces

of

a

powder

material.

Such

inter-particulate

porosity

is

determined

by

the

particle

size

and

shape

of

the

powder

grains,

essentially

reflecting

the

packing

properties

of

powder

particles.

Understanding

inter-particulate

porosity

becomes

very

significant

when

a

powder

is

used

in

the

fabrication

of

a

solid

article.

Combined

with

the

process

conditions,

such

as

compression,

binder

composition

and

firing

temperature

it

determines the porosity within the finished article.

Mesopores and Macropores

Mercury porosimetry for the pore size range 3.5 nm – 650 µm*

Pore Volume (numerical value and graphical plot)

Pore Area (numerical value and graphical plot)

Average Pore Size (numerical values)

Pore Size Distribution (numerical value and graphical plot)

Bulk and Skeletal Density

Absolute Porosity (% volume)

Permeability

Pore Tortuosity

* Depending on nature of sample

Mesopores and Small Macropores

Gas adsorption for the pore size range 2 - ~300 nm*

Specific (BET) Surface Area

Pore Volume

Pore Area

Average Pore Size

Pore Size Distribution

Assessment of Pore Geometry

Micropore Volume

Choice of Adsorbates

* Depending on nature of sample

Micropores

Gas adsorption for the pore size range 0.3 – 2 nm

Pore Volume (numerical value and graphical plot)

Pore Area (numerical value and graphical plot)

Average Pore Size (numerical values)

Nitrogen Adsorption (pores 0.45 – 2 nm)

Nitrogen Adsorption Full Isotherm (pores 0.45 - ~300nm*)

Carbon Dioxide Adsorption (pores 0.3 – 0.45 nm)

Combined CO2 and N2 Isotherms (pores 0.3 - ~300nm*)

Choice of Adsorbates (N

2

, CO

2

, Ar, H

2

, O

2

)