Key Analytical Techniques

BET Surface Area - including krypton adsorption for low area materials

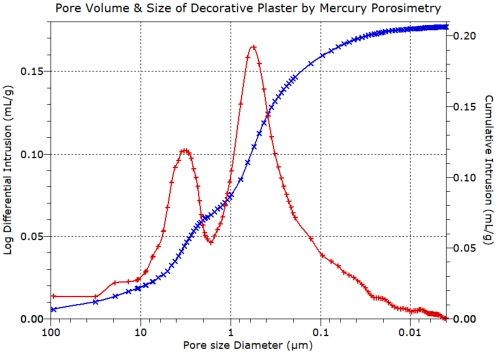

Mercury Intrusion Porosimetry - pore size, volume & area distribution

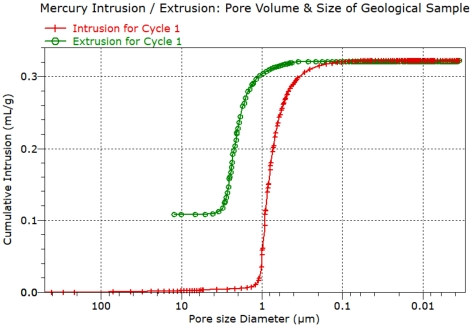

Mercury Extrusion Porosimetry - for cavity to throat size evaluation

Permeability and Tortuosity measurement via Mercury Porosimetry

Gas Adsorption - mesopore size, area and volume distribution

Micropore Analysis - pore size, area and volume distribution

Density measurement - absolute, bulk density, skeletal & particle

Specific probe gases, e.g. H

2

, CO

2

, O

2

etc

Key Applications

Porous characterisation of geological samples

Porous characterisation of construction materials

Porosity characterisation for fluid flow and retention

Porosity characterisation for gas storage and retention

Interaction with specific gases: hydrogen and CO

2

Assessment of ageing, disintegration and life-cycle

Product development: constituents and blends

Product application and surface treatments

Understanding

the

porous

characteristics

of

solid

materials

is

often

of

critical

importance

throughout

geological

and

construction

industries.

Porosity

directly

determines

the

behaviour

between

a

material

and

a

fluid

media:

this

includes

fluid

flow

through

a

sample,

fluid

retention,

drying

and curing properties, degradation characteristics and adhesion properties.

The

porosity

of

geological

materials

is

of

great

importance

across

disciplines

of

hydro-geology,

petrology,

environmental

engineering

and

geo-

chemistry.

Pore

sizes

can

vary

enormously:

larger

pores

have

a

greater

interaction

with

fluid

media

whilst

smaller

pores

are

of

particular

importance

to

gaseous

permittivity,

retention

and

storage.

Understanding

porosity

within

small

pores

is,

therefore,

of

critical

importance

to

sectors concerned with both conventional and un-conventional energy and net-zero technologies.

The

interaction

of

fluids

with

construction

materials

is

significant

throughout

their

life-cycle,

from

drying

and

curing

characteristics

of

concretes

and

coatings

to

through

the

aging

process

-

ultimately

influencing

their

life-time

and

degradation

characteristics.

The

porosity

of

the

constituent

powder

materials

or

powder

blend

heavily

influences

the

usage

and

performance

characteristics

of

the

materials,

for

example

drying

times,

shelf

life and adhesion qualities.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

ranges

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application.

Combined

with

state-of-the-art

instrumentation

and

software,

offering

flexible

and extensive reporting options, we help to maximise the amount of high quality data describing sample materials.

Tel: 01763 262333

Physical Characterisation of Geological and Construction Materials

MCA Services

01763 262333

Key Applications

Porous characterisation of geological samples

Porous characterisation of construction materials

Porosity characterisation for fluid flow and retention

Porosity characterisation for gas storage and retention

Interaction with specific gases: hydrogen and CO

2

Assessment of ageing, disintegration and life-cycle

Product development: constituents and blends

Product application and surface treatments

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

ranges

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application.

Combined

with

state-of-the-art

instrumentation

and

software,

offering

flexible

and

extensive

reporting

options,

we

help

to

maximise

the

amount

of high quality data describing sample materials.

Physical Characterisation

Geological and Construction Materials

Key Analytical Techniques

BET Surface Area - including krypton adsorption for low area

materials

Mercury Intrusion Porosimetry - pore size, pore volume &

pore area distribution

Mercury Extrusion Porosimetry - for cavity to throat size

evaluation

Permeability and Tortuosity measurement via Mercury Porosimetry

Gas Adsorption - pore size, area and volume distribution in the

mesopore range

Micropore Analysis - pore size, area and volume distribution,

pores < 2nm dia

Density measurement - absolute density, bulk density, skeletal

density & particle density

Specific probe gases, e.g. H

2

, CO

2

, O

2

etc available for

adsorption capacity measurement

Understanding

the

porous

characteristics

of

solid

materials

is

often

of

critical

importance

throughout

geological

and

construction

industries.

Porosity

directly

determines

the

behaviour

between

a

material

and

a

fluid

media:

this

includes

fluid

flow

through

a

sample,

fluid

retention,

drying

and

curing

properties, degradation characteristics and adhesion properties.

The

porosity

of

geological

materials

is

of

great

importance

across

disciplines

of

hydro-geology,

petrology,

environmental

engineering

and

geo-chemistry.

Pore

sizes

can

vary

enormously:

larger

pores

have

a

greater

interaction

with

fluid

media

whilst

smaller

pores

are

of

particular

importance

to

gaseous

permittivity,

retention

and

storage.

Understanding

porosity

within

small

pores

is,

therefore,

of

critical

importance

to

sectors

concerned

with

both

conventional

and

un-conventional

energy

and net-zero technologies.

The

interaction

of

fluids

with

construction

materials

is

significant

throughout

their

life-cycle,

from

drying

and

curing

characteristics

of

concretes

and

coatings

to

through

the

ageing

process

-

ultimately

influencing

their

life-time

and

degradation

characteristics.

The

porosity

of

the

constituent

powder

materials

or

powder

blend

heavily

influences

the

usage

and

performance

characteristics

of

the

materials,

for

example

drying

times,

shelf

life and adhesion qualities.