Porosity

in

pharmaceutical

materials

can

be

present

in

various

locations:

within

tablet

cores

and

granules,

coatings,

and

within

the

particles

of

a

pre-cursor

powder

blend

and

also

the

void

spaces

between

powder

particles.

The

latter

dictates

the

porous

characteristics

of

tableted

forms.

SSA

measurement

is

routinely

and

usefully

applied

to

the

characterisation

of

powder

samples

but

the

pore

sizes

present

commonly

fall

within

the

range

measured

by

the

mercury

porosimetry

technique.

This

provides

a

complete

picture

of

pore

size,

pore

volume,

volume

porosity

and

density.

It

can

also

provide

insight

to

pore

geometry.

These

porosity

characteristics

then

dictate

performance

behaviours,

may

be

indicative

of

atypical

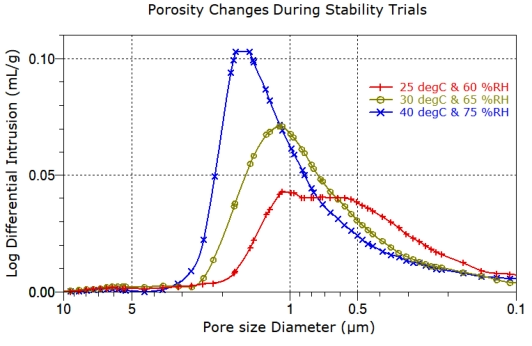

performance, and often change during the ageing processes applied during stability trials.

Tel: 01763 262333

Pharmaceutical Characterisation at MCA Services

The

physical

characteristics

of

pharmaceuticals

profoundly

influence

the

properties

and

effectiveness

of

the

final

dosage

form,

be

it

administered

via

tablet,

granule

/

capsule

or

inhalation

routes.

Furthermore,

knowledge

of

physical

characteristics

often

contributes

to

the

critical

understanding

of

all

components,

such

as

API,

excipients,

powder

blends

and

ribbons

as

well

as

the

final

form.

They

are

also

applicable

to

all

stages

of

pharmaceutical processes: from formulation through manufacturing to quality control, stability trials and trouble-shooting atypical behaviour.

Physical

characteristics

commonly

include

specific

surface

area

(SSA),

pore

size

and

volume

distributions

and

density,

which

together

provide

a

complete

understanding

of

overall

porosity.

In

turn,

porosity

has

direct

effects

on

many

aspects

of

performance,

for

example

dissolution

and

disintegration

rates,

strength

and

hardness

and

long

term

stability

of

solid

dosage

forms.

They

also

influence

formulation

and

effect

stability

of

solid components in many emulsion, paste and topical forms.

Key Applications

Characterisation of API and excipient materials

Characterisation of powder blends

Investigation of dissolution rate

Study of disintegration

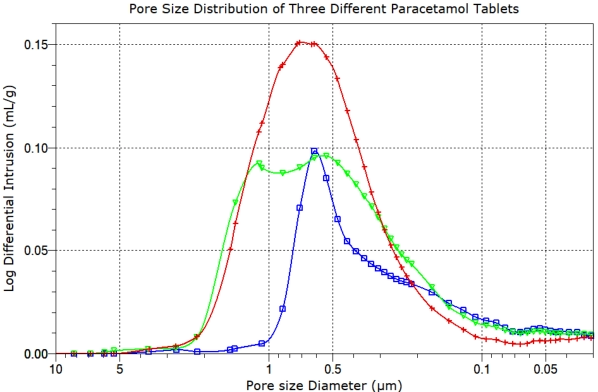

Investigation of batch failures and inter-batch variability

Influence of stability trials on porosity

Determination of long-term stability and shelf life

Investigation and establishment of tableting conditions

Identification of counterfeit batches

Significant to approval processes

All analyses undertaken to ISO 17025 standards

Key Analytical Techniques

Mercury Porosimetry

Pore volume Distribution

Pore Size Distribution

Pore Area Distribution

Absolute Porosity

Bulk and Skeletal Density

Pore Geometry

Permeability Measurement

Applicable to all solid forms

Gas Adsorption

BET Specific Surface Area by Nitrogen

BET Specific Surface Area by Krypton (low SSA)

Micro-pore / Meso-pore characterisation

Pore volume Distribution

Pore Size Distribution

Pore Area Distribution

At

MCA

Services

we

offer

a

suite

of

analytical

techniques

for

the

complete

characterisation

of

pharmaceutical

samples.

This

is

combined

with

the

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results

directly

relating

these

to

performance

characteristics

of

the

material.

We

have

many

years

of

experience

partnering

with

the

pharmaceutical

sector,

considering

a

wide

variety

of

dosage

forms

and

applications,

from

formulation to stability trials and identification of the influence of porosity to materials and batches having atypical behaviour.

Pharmaceutical Characterisation

The

physical

characteristics

of

pharmaceuticals

profoundly

influence

the

properties

and

effectiveness

of

the

final

dosage

form,

be

it

administered

via

tablet,

granule

/

capsule

or

inhalation

routes.

Furthermore,

knowledge

of

physical

characteristics

often

contributes

to

the

critical

understanding

of

all

components,

such

as

API,

excipients,

powder

blends

and

ribbons

as

well

as

the

final

form.

They

are

also

applicable

to

all

stages

of

pharmaceutical

processes:

from

formulation

through

manufacturing

to

quality

control, stability trials and trouble-shooting atypical behaviour.

Physical

characteristics

commonly

include

specific

surface

area

(SSA),

pore

size

and

volume

distributions

and

density,

which

together

provide

a

complete

understanding

of

overall

porosity.

In

turn,

porosity

has

direct

effects

on

many

aspects

of

performance,

for

example

dissolution

and

disintegration

rates,

strength

and

hardness

and

long

term

stability

of

solid

dosage

forms.

They

also

influence

formulation

and

effect

stability

of

solid

components

in

many emulsion, paste and topical forms.

Key Applications

Characterisation of API and excipient materials

Characterisation of powder blends

Dissolution rate study

Disintegration study

Investigation of batch failures and inter-batch variability

Influence of stability trials on porosity

Determination of long-term stability and shelf life

Investigation and establishment of tabletting conditions

Identification of counterfeit batches

Significant to approval processes

All analyses undertaken to ISO 17025 standards

Porosity

in

pharmaceutical

materials

can

be

present

in

various

locations:

within

tablet

cores

and

granules,

coatings,

and

within

the

particles

of

a

pre-cursor

powder

blend

and

also

the

void

spaces

between

powder

particles.

The

latter

dictates

the

porous

characteristics

of

tableted

forms.

SSA

measurement

is

routinely

and

usefully

applied

to

the

characterisation

of

powder

samples

but

the

pore

sizes

present

commonly

fall

within

the

range

measured

by

the

mercury

porosimetry

technique.

This

provides

a

complete

picture

of

pore

size,

pore

volume,

volume

porosity

and

density.

It

can

also

provide

insight

to

pore

geometry.

These

porosity

characteristics

then

dictate

performance

behaviours,

may

be

indicative

of

atypical

performance,

and

often

change

during the aging processes applied during stability trials.

Key Analytical Techniques

Mercury Porosimetry

Pore volume Distribution

Pore Size Distribution

Pore Area Distribution

Absolute Porosity

Bulk and Skeletal Density

Pore Geometry

Permeability Measurement

Applicable to all solid forms

Gas Adsorption

BET Specific Surface Area by Nitrogen

BET Specific Surface Area by Krypton (low SSA)

Micro-pore / Meso-pore characterisation

Pore volume Distribution

Pore Size Distribution

Pore Area Distribution

At

MCA

Services

we

offer

a

suite

of

analytical

techniques

for

the

complete

characterisation

of

pharmaceutical

samples.

This

is

combined

with

the

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results

directly

relating

these

to

performance

characteristics

of

the

material.

We

have

many

years

of

experience

partnering

with

the

pharmaceutical

sector,

considering

a

wide

variety

of

dosage

forms

and

applications,

from

formulation

to

stability

trials

and

identification

of

the

influence

of

porosity to materials and batches having atypical behaviour.