Tel: 01763 262333

Temperature Programmed Analytical Options

Temperature Programmed Desorption (TPD)

Temperature Programmed Reduction (TPR)

Temperature Programmed Oxidation (TPO)

Temperature

programmed

analyses

are

part

of

our

suite

of

chemisorption

options,

used

to

investigate

reduction,

oxidation,

desorption

and

decomposition

as

a

function

of

temperature.

Traditionally

these

have

been

applied

to

the

catalysis

sector

where

the

understanding

of

surface

reactions

are

fundamental

to

the

development

and

regeneration

of

high

efficiency

systems.

The

use

of

these

techniques

is

often

extended

to

other

sectors

and

applications,

wherever

the

behaviour

of

oxidisable

or

reducible

species

is

of

importance

or

for

the

study

and

development

of

adsorbents and filter materials.

Temperature

programmed

analyses

at

MCA

Services

are

undertaken

using

our

state-of-the-art

Micromeritics

AutoChem

instrument,

capable

of

analyses

from

sub-ambient

temperature

to

1100

°C.

Furthermore,

this

instrument

provides

tremendous

scope

for

accurate

selection

and

control

over

analytical

parameters

such

as

gas

flow

rate,

temperature

ramp

rate

and

temperature

holding

ranges.

The

instrument

detector

is

always

calibrated to match specific analytical parameters, ensuring the accurate calculation of specific active gas consumption.

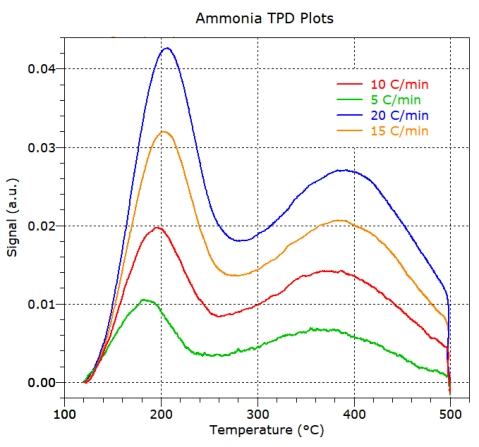

Temperature Programmed Desorption (TPD)

Temperature

programmed

desorption

is

used

to

study

the

temperature

dependence

and

strength

of

interaction

between

a

sample

surface

and

a

probe

molecule.

Typical

probe

molecules

include

H2,

CO

and

NH3,

although

others,

including

vapours,

can

also

be

applied

in

order

to

investigate

specific

systems.

Initial

adsorption,

either

physical

or

chemical,

is

usually

conducted

at

ambient

temperature,

although

sub-ambient

conditions

can

also

be

applied.

The

desorption

process

is

then

measured

with

steady

increasing

sample

temperature

under

inert

gas

flow.

Recording

the

temperature

at

which

desorption

occurs

and

accurately

measuring

the

volume

of

gas

desorbing

allows

for

the

determination

of

the

number

and

strength

of

active

adsorption

sites

on

a

sample

surface.

Temperature

programmed

desorption

can

also

be

extended

to

investigate

sample

materials

when

the

adsorption

/

desorption

processes

are

significant

to

performance,

for

example

effectiveness

and

regeneration of adsorbents, filter materials and catalysts.

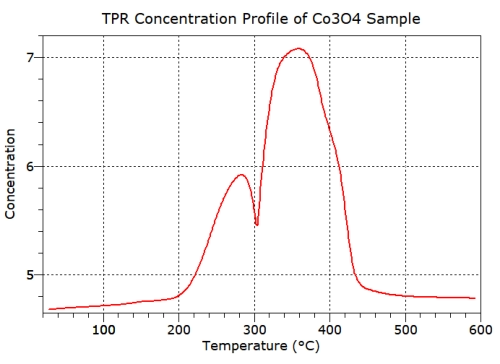

Temperature Programmed Reduction (TPR)

Temperature

programmed

reduction

is

used

to

investigate

the

reducibility

of

a

species

and

can

be

applied

to

metals

and

metal

compounds

such

as

oxides

in

both

supported

and

un-supported

forms.

Historically

very

important

to

the

study

of

catalysts,

TPR

can

be

applied

to

a

wide

variety

of

metallic

and

supported

metallic

species

when

reduction

behaviour

requires

understanding.

The

analytical

process

involves

heating

a

sample

at

a

steady

rate,

to

a

maximum

of

1100

°C,

in

a

stream

of

reducing

gas,

typically

low

concentration

hydrogen

or

carbon

monoxide

balanced

with

an

inert

carrier.

Reduction

of

the

sample

is

then

recorded

using

a

thermal

conductivity

detector

(TCD)

as

the

concentration

of

the

reducing

gas

component

falls

as

it

is

consumed

during

reduction

of

the

sample.

At

MCA

Services,

the

TCD

is

calibrated

with

respect

to

reducing

gas

concentration

which

allows

for

the

calculation

of

active

gas

consumption

during

the

reduction

process.

Results

then

include

quantified

graphical

representations

of

the

reduction

process

in

relation

to

temperature

and

numerical

reducing

gas

consumption

data.

TPR,

therefore,

provides

important

information

regarding

reduction

temperature

and

gas

consumption

which

can

be

extended

to

the

identification

of

the

number

of

reducible

species

and

insight

into

the

reduction

sequence

via

intermediate

species.

This

information

is

important

to

many

process

during

application and regeneration and to the understanding of support materials, which can profoundly affect reduction behaviour.

Temperature Programmed Oxidation (TPO)

Analogous

to

TPR,

temperature

programmed

oxidation

is

applied

to

the

study

of

oxidisable

species

on

a

material

surface.

The

analytical

process

is

very

similar

to

that

of

TPR

with

oxygen

replacing

the

reducing

gas

species

in

the

carrier

stream.

Similar

data

is

also

obtained,

the

TCD

again

being

accurately

calibrated

for

oxygen

consumption,

allowing

for

the

quantified

determination

of

the

number

and

extent

of

oxidisable

species

on

the

sample

surface.

Classic

applications

of

TPO

are

within

the

catalysis

and

electro-catalysis

sectors,

whereby

it

is

very

useful

for

investigating

coking

during

use

for

many

processes

involving

hydrocarbons.

TPO

also

can

be

applied

to

many

systems

when

the

process

of

oxidation

is

of

importance,

including

stages

of

chemical

product and process development in order to maximise efficiency and yield.

At

MCA

Services

we

have

decades

of

experience

in

the

analysis

and

characterisation

of

materials

by

chemisorption

techniques

and

are

always

happy

to

discuss

specific

samples

and

applications.

The

flexibility

of

our

analytical

options

combined

with

our

expertise

ensures

that

the

most

appropriate

analytical

test,

or

combination

of

tests,

are

selected

for

your

particular

sample,

application

and

requirements.

We

also

provide

assistance

with

the

interpretation

of

results

and

more

information

about

these

analytical

options

and

the

background

operation

and

theory

can

be

found on our YouTube channel.

Temperature Programmed Analytical Options

Temperature Programmed Desorption (TPD)

Temperature Programmed Reduction (TPR)

Temperature Programmed Oxidation (TPO)

Temperature

programmed

analyses

are

part

of

our

suite

of

chemisorption

options,

used

to

investigate

reduction,

oxidation,

desorption

and

decomposition

as

a

function

of

temperature.

Traditionally

these

have

been

applied

to

the

catalysis

sector

where

the

understanding

of

surface

reactions

are

fundamental

to

the

development

and

regeneration

of

high

efficiency

systems.

The

use

of

these

techniques

is

often

extended

to

other

sectors

and

applications,

wherever

the

behaviour

of

oxidisable

or

reducible

species

is

of

importance

or

for

the

study

and

development of adsorbents and filter materials.

Temperature

programmed

analyses

at

MCA

Services

are

undertaken

using

our

state-of-the-art

Micromeritics

AutoChem

instrument,

capable

of

analyses

from

sub-ambient

temperature

to

1100

°C.

Furthermore,

this

instrument

provides

tremendous

scope

for

accurate

selection

and

control

over

analytical

parameters

such

as

gas

flow

rate,

temperature

ramp

rate

and

temperature

holding

ranges.

The

instrument

detector

is

always

calibrated

to

match

specific

analytical

parameters,

ensuring

the

accurate calculation of specific active gas consumption.

Temperature Programmed Desorption (TPD)

Temperature

programmed

desorption

is

used

to

study

the

temperature

dependence

and

strength

of

interaction

between

a

sample

surface

and

a

probe

molecule.

Typical

probe

molecules

include

H2,

CO

and

NH3,

although

others,

including

vapours,

can

also

be

applied

in

order

to

investigate

specific

systems.

Initial

adsorption,

either

physical

or

chemical,

is

usually

conducted

at

ambient

temperature,

although

sub-ambient

conditions

can

also

be

applied.

The

desorption

process

is

then

measured

with

steady

increasing

sample

temperature

under

inert

gas

flow.

Recording

the

temperature

at

which

desorption

occurs

and

accurately

measuring

the

volume

of

gas

desorbing

allows

for

the

determination

of

the

number

and

strength

of

active

adsorption

sites

on

a

sample

surface.

Temperature

programmed

desorption

can

also

be

extended

to

investigate

sample

materials

when

the

adsorption

/

desorption

processes

are

significant

to

performance,

for

example

effectiveness

and

regeneration

of

adsorbents,

filter

materials and catalysts.

Temperature Programmed Reduction (TPR)

Temperature

programmed

reduction

is

used

to

investigate

the

reducibility

of

a

species

and

can

be

applied

to

metals

and

metal

compounds

such

as

oxides

in

both

supported

and

un-supported

forms.

Historically

very

important

to

the

study

of

catalysts,

TPR

can

be

applied

to

a

wide

variety

of

metallic

and

supported

metallic

species

when

reduction

behaviour

requires

understanding.

The

analytical

process

involves

heating

a

sample

at

a

steady

rate,

to

a

maximum

of

1100

°C,

in

a

stream

of

reducing

gas,

typically

low

concentration

hydrogen

or

carbon

monoxide

balanced

with

an

inert

carrier.

Reduction

of

the

sample

is

then

recorded

using

a

thermal

conductivity

detector

(TCD)

as

the

concentration

of

the

reducing

gas

component

falls

as

it

is

consumed

during

reduction

of

the

sample.

At

MCA

Services,

the

TCD

is

calibrated

with

respect

to

reducing

gas

concentration

which

allows

for

the

calculation

of

active

gas

consumption

during

the

reduction

process.

Results

then

include

quantified

graphical

representations

of

the

reduction

process

in

relation

to

temperature

and

numerical

reducing

gas

consumption

data.

TPR,

therefore,

provides

important

information

regarding

reduction

temperature

and

gas

consumption

which

can

be

extended

to

the

identification

of

the

number

of

reducible

species

and

insight

into

the

reduction

sequence

via

intermediate

species.

This

information

is

important

to

many

process

during

application

and

regeneration

and

to

the

understanding

of

support

materials,

which

can

profoundly affect reduction behaviour.

Temperature Programmed Oxidation (TPO)

Analogous

to

TPR,

temperature

programmed

oxidation

is

applied

to

the

study

of

oxidisable

species

on

a

material

surface.

The

analytical

process

is

very

similar

to

that

of

TPR

with

oxygen

replacing

the

reducing

gas

species

in

the

carrier

stream.

Similar

data

is

also

obtained,

the

TCD

again

being

accurately

calibrated

for

oxygen

consumption,

allowing

for

the

quantified

determination

of

the

number

and

extent

of

oxidisable

species

on

the

sample

surface.

Classic

applications

of

TPO

are

within

the

catalysis

and

electro-catalysis

sectors,

whereby

it

is

very

useful

for

investigating

coking

during

use

for

many

processes

involving

hydrocarbons.

TPO

also

can

be

applied

to

many

systems

when

the

process

of

oxidation

is

of

importance,

including

stages

of

chemical

product

and

process

development

in

order

to

maximise

efficiency and yield.

At

MCA

Services

we

have

decades

of

experience

in

the

analysis

and

characterisation

of

materials

by

chemisorption

techniques

and

are

always

happy

to

discuss

specific

samples

and

applications.

The

flexibility

of

our

analytical

options

combined

with

our

expertise

ensures

that

the

most

appropriate

analytical

test,

or

combination

of

tests,

are

selected

for

your

particular

sample,

application

and

requirements.

We

also

provide

assistance

with

the

interpretation

of

results

and

more

information

about

these

analytical

options

and

the

background

operation

and

theory

can be found on our YouTube channel.