Tel: 01763 262333

Mercury Porosimetry

Mesopore and Macropore Size, Volume & Area Measurement

Mercury

porosimetry

provides

a

wealth

of

information

for

understanding

the

porous

characteristics

of

any

material

with

porosity

in

the

size

range

3.5

nm

to

650

µm.

The

technique

is

applicable

to

virtually

any

solid

form,

from

powders,

through

granules

to

single

solid

pieces,

films,

membranes,

fabrics

and

coatings.

The

pore

volume,

pore

area

and

pore

size

present

in

solid

materials

and

between

the

particles

of

powder

and

granules

often

profoundly

affect

the

fabrication

and

performance

of

materials.

Porosity

influences

the

efficiency,

efficacy

and

functionality

of

materials

across

sectors

such

as

pharmaceuticals,

catalysis,

energy

production

and

storage,

sorption

technology

and

geology

&

environmental

science

and

construction.

It

is

usually

necessary

to

consider

the

extent,

nature

and

effects

of

porosity

at

all

stages

of

product

life-cycle,

from

the

characterisation

of

raw

materials,

through

formulation

and

fabrication

processes

to

final

use

and

application.

Knowledge

of

the

full

porous

character of materials is, therefore, critical to the understanding of materials and their application.

Key Applications

Analysis of wide range of pore sizes 3.5nm to 650 µm

Applicable to almost any solid sample form

Dissolution rate of pharmaceutical tablets and granules

Pharmaceutical powder blends and resulting solid dose forms

Assessment of powder inter-particulate size and volume

Ceramic raw material and finished product characterisation

Efficiency and efficacy of filter media

Chemical activity of catalysts and electrocatalysts

Fabrication of battery electrode, separator and solid electrolytes

Capacity and efficiency of battery electrodes and materials

Production and performance of construction materials

Production and performance of coatings and abrasives

Characterisation of geological samples and fluid interactions

Product life-cycle and capacity assessment

Investigations of atypical performance and failures

Mercury

porosimetry

is

an

exceptionally

powerful

analytical

technique

for

studying

materials

with

porosity

in

the

mesopore

and

macropore

ranges.

At

MCA

Services

we

use

the

latest,

state-of-the-art

Micromeritics

AutoPore

V

instrument

to

offer

a

comprehensive

list

of

flexible

analytical

and

reporting

options.

Combined

with

our

decades

of

experience,

we

are

able

to

recommend

and

tailor

analyses

to

your

materials

and

their

performance

in

specific

applications.

We

are

also

happy

to

assist

with

data

interpretation

so

that

you

receive

the

most

pertinent

data

and

gain

the

maximum

insight

into

your

materials

and

their

efficiency.

More

information

about

mercury

porosimetry,

its

use

and

background

theory,

is

available

on our YouTube channel.

Analytical Options and Highlights

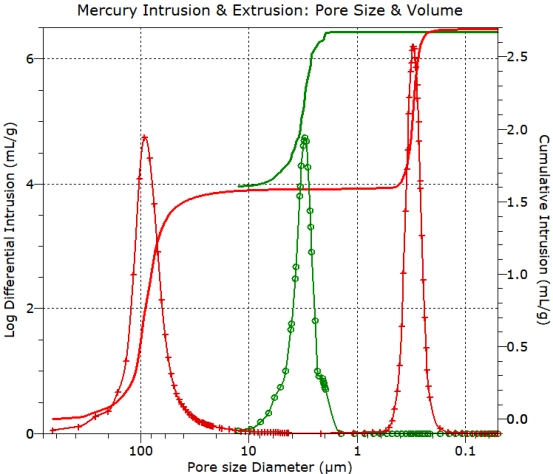

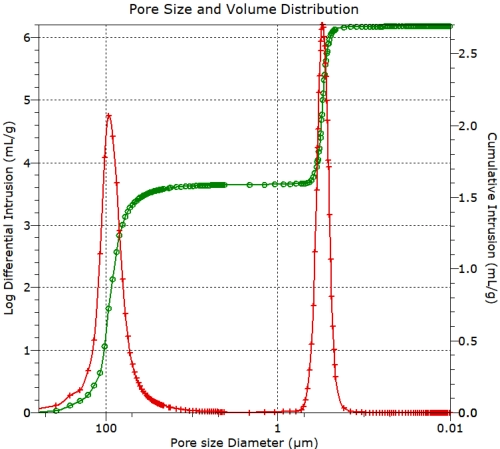

Pore volume (numerical and graphical reports)

Pore Size Distribution (numerical and graphical reports)

Pore Area (numerical and graphical reports)

Average pore size by numerous calculations

Additional calculation of bulk and skeletal density

Additional calculation of absolute porosity (% volume)

Characterisation of inter-particulate and intra-particulate porosity

Permeability and Tortuosity measurement

Mercury intrusion and intrusion / extrusion options

Pore geometry assessment and cavity-to-throat size ratio

Assessment of particle size via Mayer-Stowe method

Extensive and flexible reporting options

For

materials

having

pores

smaller

than

3.5nm

our

gas

adsorption

options

are

applicable.

Alternatively,

the

two

techniques:

nitrogen

adsorption

and

mercury

porosimetry

can

be

combined

to

provide

a

full

characterisation

of

micropores,

mesopores

and

macropores.

In

addition

to

our

standard

reporting

options

we

can

generate

alternative

representations,

provide

graphical

overlay

plots

to

enable

direct

comparison

of

multiple

samples and also raw data for further inclusion in reports and presentations.

Mercury Porosimetry

Mesopore and Macropore Size, Volume & Area Measurement

Mercury

porosimetry

provides

a

wealth

of

information

for

understanding

the

porous

characteristics

of

any

material

with

porosity

in

the

size

range

3.5

nm

to

650

µm.

The

technique

is

applicable

to

virtually

any

solid

form,

from

powders,

through

granules

to

single

solid

pieces,

films,

membranes,

fabrics

and

coatings.

The

pore

volume,

pore

area

and

pore

size

present

in

solid

materials

and

between

the

particles

of

powder

and

granules

often

profoundly

affect

the

fabrication

and

performance

of

materials.

Porosity

influences

the

efficiency,

efficacy

and

functionality

of

materials

across

sectors

such

as

pharmaceuticals,

catalysis,

energy

production

and

storage,

sorption

technology

and

geology

&

environmental

science

and

construction.

It

is

usually

necessary

to

consider

the

extent,

nature

and

effects

of

porosity

at

all

stages

of

product

life-cycle,

from

the

characterisation

of

raw

materials,

through

formulation

and

fabrication

processes

to

final

use

and

application.

Knowledge

of

the

full

porous

character

of

materials

is,

therefore,

critical

to

the

understanding of materials and their application.

Key Applications

Analysis of wide range of pore sizes 3.5nm to 650 µm

Applicable to almost any solid sample form

Dissolution rate of pharmaceutical tablets and granules

Pharmaceutical powder blends and solid dose forms

Assessment of powder inter-particulate size and volume

Ceramic raw material and finished product characterisation

Efficiency and efficacy of filter media

Chemical activity of catalysts and electrocatalysts

Fabrication of battery electrodes

Battery separator and solid electrolytes selection

Capacity and efficiency of battery electrodes and materials

Production and performance of construction materials

Production and performance of coatings and abrasives

Characterisation of geological samples and fluid interactions

Product life-cycle and capacity assessment

Investigations of atypical performance and failures

Mercury

porosimetry

is

an

exceptionally

powerful

analytical

technique

for

studying

materials

with

porosity

in

the

mesopore

and

macropore

ranges.

At

MCA

Services

we

use

the

latest,

state-

of-the-art

Micromeritics

AutoPore

V

instrument

to

offer

a

comprehensive

list

of

flexible

analytical

and

reporting

options.

Combined

with

our

decades

of

experience,

we

are

able

to

recommend

and

tailor

analyses

to

your

materials

and

their

performance

in

specific

applications.

We

are

also

happy

to

assist

with

data

interpretation

so

that

you

receive

the

most

pertinent

data

and

gain

the

maximum

insight

into

your

materials

and

their

efficiency.

More

information

about

mercury

porosimetry,

its

use

and background theory, is available on our YouTube channel.

Analytical Options and Highlights

Pore volume (numerical and graphical reports)

Pore Size Distribution (numerical and graphical reports)

Pore Area (numerical and graphical reports)

Average pore size by numerous calculations

Additional calculation of bulk and skeletal density

Additional calculation of absolute porosity (% volume)

Characterisation of inter-particulate porosity

Characterisation of intra-particulate porosity

Permeability and Tortuosity measurement

Mercury intrusion and intrusion / extrusion options

Pore geometry assessment and cavity-to-throat size ratio

Assessment of particle size via Mayer-Stowe method

Extensive and flexible reporting options

For

materials

having

pores

smaller

than

3.5nm

our

gas

adsorption

options

are

applicable.

Alternatively,

the

two

techniques:

nitrogen

adsorption

and

mercury

porosimetry

can

be

combined

to

provide

a

full

characterisation

of

micropores,

mesopores

and

macropores.

In

addition

to

our

standard

reporting

options

we

can

generate

alternative

representations,

provide

graphical

overlay

plots

to

enable

direct

comparison

of

multiple

samples

and

also

raw

data

for

further

inclusion

in

reports and presentations.