Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End, Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

Chemisorption Analysis (Chemical Adsorption)

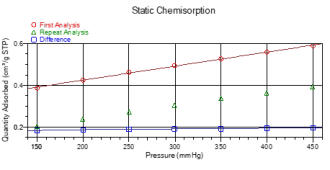

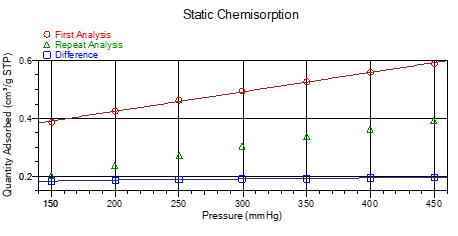

Static Chemisorption

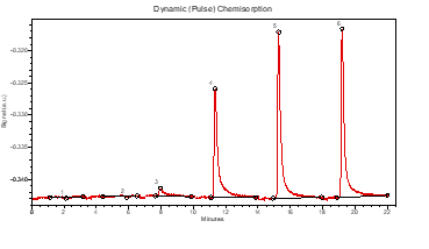

Dynamic (Pulse) Chemisorption

CO, H2 and O2 Chemisorption Options

Chemical

adsorption,

or

chemisorption

analysis,

concerns

the

formation

of

chemical

bonds

between

an

adsorptive

gas

and

the

active

surface

sites

on

a

sample.

Chemisorption

is

particularly

suited

to

the

characterisation

and

optimisation

of

catalysts.

Chemisorption

is

used

to

determine

the

surface

area,

dispersion

and

crystallite

size

of

active

metals

in

a

catalyst.

These

essentially

provide

critical

information

regarding

the

surface

chemistry

of

a

sample

and

the

availability

of

the

catalytically-active

constituents.

With

this

information

it

is

possible

to

assess

the

efficiency

of

a

catalyst

sample

for

a

given

chemical

reaction,

which

is

critical

to

the

development

of

catalytic

materials.

Alternatively,

chemisorption can be applied to functioning catalysts in order to monitor degradation over time and assess the success of re-generation.

Key Information.

•

Static chemisorption analysis

•

Dynamic (pulse) analysis

•

Choice of analysis temperature

•

Choice of in-situ pre-reduction conditions

•

Carbon monoxide chemisorption

•

Hydrogen chemisorption

•

Oxygen chemisorption

•

Other probe gases available in request

•

Metal dispersion (%)

•

Metallic (active) surface area of metal

•

Metallic (active) surface area of sample

•

Crystallite size (nm)

•

At

MCA

Services

we

offer

two

different

chemisorption

techniques,

both

using

the

state-of-the-art

Micromeritics

3Flex

TCD

Chemisorption

instrument.

Static

chemisorption

is

undertaken

at

a

constant

temperature

over

a

range

of

relative

pressures

with

two

adsorption

isotherms

being

measured.

The

first

isotherm

is

due

to

both

chemically

(strong)

and

physically

(weak)

adsorbed

species

whereas

the

second

isotherm

is

due

solely

to

physisorbed

species.

The

volume

chemically

adsorbed

onto

the

sample

can

then

be

determined

and

applied

to

calculation

of

active

metal area, dispersion, etc.

Dynamic,

or

pulse

chemisorption,

is

undertaken

at

atmospheric

pressure

using

a

flowing

gas

technique.

Successive

injections

of

a

calibrated

volume

of

adsorptive

gas

are

made

to

the

sample

and

a

TCD

(Thermal

Conductivity

Detector)

is

used

to

measure

the

volume

of

adsorptive

gas

which

is

not

chemisorbed

onto

the

sample.

The

sample

is

saturated

with

adsorptive

gas

when

a

complete

injection

is

passed

through

to

the

TCD, the volume of adsorptive chemisorbed can then be calculated and applied the to calculation of active metal area, dispersion, etc.

Alternative

chemisorption

analyses

include

a

range

of

temperature

programmed

techniques,

such

as

TPD,

TPR

and

TPD,

please

see

our

Temperature Programmed Analyses page for more details.

Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End,

Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

Chemisorption Analysis (Chemical Adsorption)

Static Chemisorption

Dynamic (Pulse) Chemisorption

CO, H2 and O2 Chemisorption Options

Chemical

adsorption,

or

chemisorption

analysis,

concerns

the

formation

of

chemical

bonds

between

an

adsorptive

gas

and

the

active

surface

sites

on

a

sample.

Chemisorption

is

particularly

suited

to

the

characterisation

and

optimisation

of

catalysts.

Chemisorption

is

used

to

determine

the

surface

area,

dispersion

and

crystallite

size

of

active

metals

in

a

catalyst.

These

essentially

provide

critical

information

regarding

the

surface

chemistry

of

a

sample

and

the

availability

of

the

catalytically-active

constituents.

With

this

information

it

is

possible

to

assess

the

efficiency

of

a

catalyst

sample

for

a

given

chemical

reaction,

which

is

critical

to

the

development

of

catalytic

materials.

Alternatively,

chemisorption

can

be

applied

to

functioning

catalysts

in

order

to

monitor degradation over time and assess the success of re-generation.

Key Information.

•

Static chemisorption analysis

•

Dynamic (pulse) analysis

•

Choice of analysis temperature

•

Choice of in-situ pre-reduction conditions

•

Carbon monoxide chemisorption

•

Hydrogen chemisorption

•

Oxygen chemisorption

•

Other probe gases available in request

•

Metal dispersion (%)

•

Metallic (active) surface area of metal

•

Metallic (active) surface area of sample

•

Crystallite size (nm)

•

At

MCA

Services

we

offer

two

different

chemisorption

techniques,

both

using

the

state-of-the-art

Micromeritics

3Flex

TCD

Chemisorption

instrument.

Static

chemisorption

is

undertaken

at

a

constant

temperature

over

a

range

of

relative

pressures

with

two

adsorption

isotherms

being

measured.

The

first

isotherm

is

due

to

both

chemically

(strong)

and

physically

(weak)

adsorbed

species

whereas

the

second

isotherm

is

due

solely

to

physisorbed

species.

The

volume

chemically

adsorbed

onto

the

sample

can

then

be

determined

and

applied

to

calculation

of

active

metal area, dispersion, etc.

Dynamic,

or

pulse

chemisorption,

is

undertaken

at

atmospheric

pressure

using

a

flowing

gas

technique.

Successive

injections

of

a

calibrated

volume

of

adsorptive

gas

are

made

to

the

sample

and

a

TCD

(Thermal

Conductivity

Detector)

is

used

to

measure

the

volume

of

adsorptive

gas

which

is

not

chemisorbed

onto

the

sample.

The

sample

is

saturated

with

adsorptive

gas

when

a

complete

injection

is

passed

through

to

the

TCD,

the

volume

of

adsorptive

chemisorbed

can

then

be

calculated

and

applied the to calculation of active metal area, dispersion, etc.

Alternative

chemisorption

analyses

include

a

range

of

temperature

programmed

techniques,

such

as

TPD,

TPR

and

TPD,

please

see

our

Temperature Programmed Analyses page for more details.

01763262333