Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End, Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

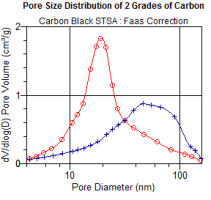

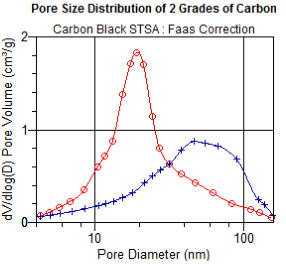

Our

gas

adsorption

and

mercury

porosimetry

techniques

are

applicable

to

the

investigation

of

component

materials,

such

as

carbons,

graphites

and

active

cathode

materials.

An

understanding

of

the

porous

nature

of

these

is

vital

for

determining

packing

characteristics,

electrode

conductivity

and

electrochemical

activity.

Careful

selection

of

raw

materials

having

optimum

porosity

is

often

required

so

that

a

desired balance between efficiency and cycling lifetime is achieved.

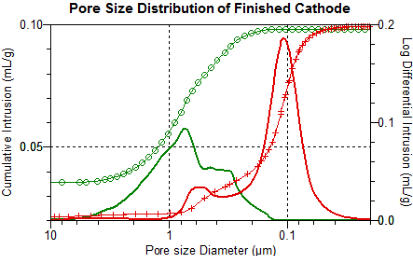

The

porous

nature

of

finished

electrodes

is

likely

to

be

different

from

the

components

materials

due

to

processing

and

additives.

However,

this

porosity

exerts

profound

influence

over

electrolyte

transport,

conductivity,

availability

of

active

reaction

sites,

mechanical

stress,

charge

/

discharge

characteristics

and

cycling

lifetime.

Mercury

porosimetry

is

ideally

suited

to

the

characterisation

of

finished

electrodes

and

can

be

extended

to

measure

the

tortuosity

of

a

pore

network,

providing

vital

information

relating

to

many

of

these

performance measures.

Mercury

porosimetry

is

also

applicable

to

the

determination

of

the

porous

structure

of

separator

materials,

where

a

tight

distribution

of

pores of a certain size is demanded for efficient transfer properties.

For

active

metal

impregnated

systems,

the

active

metal

surface

area

and

dispersion

can

be

measured

accurately

by

chemisorption

(chemical

adsorption).

MCA

Services

offers

a

range

of

adsorptive

options,

CO

and

H

2

being

commonly

applied,

and

two

techniques:

static

and dynamic (pulse) chemisorption. A wide range of active metals and metal loading s can, therefore, be characterised.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

porosity

with

the

experience

and

expertise

to

actively

assist

with

interpretation

of

results.

We

have

extensive

experience

in

the

characterisation

of

carbons

and

graphites

as

well

as

research

and

development

of

Li-ion

battery

technology.

Our

ongoing

in-house

research

has

focused

on

battery

and

super-capacitor

applications:

a

field

in which we have journal publications.

Key Techniques:·

BET Surface Area - by nitrogen or krypton adsorption

Micropore Analysis - pore size, area and volume distribution

Gas Adsorption - pore size, area and volume distribution in the mesopore range

Mercury Porosimetry - for pore size, pore volume & pore area distribution

Mercury Porosimetry - for cavity to throat size evaluation

Permeability and Tortuosity measurement via Mercury Porosimetry & Pycnometry

Chemisorption by a range of gases for analysis of catalysts

Density measurement - absolute density, bulk density & skeletal density

Total Pore Volume and Solid Fraction measurement

CHARACTERISATION OF BATTERY COMPONENTS

The

porous

nature

of

electrode

components,

finished

electrode

architectures

and

separator

materials

is

critical

to

the

performance

optimisation

of

battery

systems.

Pore

volume

and

pore

size

distribution

have

profound

effects

on

energy

density,

electrolyte

transport

characteristics,

electrode

conductivity,

cycling

lifetime

&

degradation

and

availability

of

active

sites

for

electrochemical

reaction.

When

electrode

materials

contain

active

metals

doped

to

a

substrate, their dispersion and surface area have a primary influence over battery performance and efficiency.

The

understanding

of

the

porosity

of

battery

components

is,

therefore,

necessary

at

all

stages

of

battery

development:

materials

selection,

production

and

failure

analysis.

Measuring

the

dispersion

and

surface

area

of

active metals by chemisorption is a valuable tool for the understanding and optimisation of battery systems.

Key Benefits:

•

Pore volume and pore size distribution characterisation

•

Tortuosity measurement for studying pore networks

•

Characterisation of component material porosity

•

Characterisation of finished electrode porosity

•

Measurement of active metal properties via chemisorption

•

Establishing process control settings for electrode manufacture

•

Characterisation of separator porosity

•

Assistance with data interpretation

•

Expansive data presentation and comparative overlay options

•

Highly experienced in catalysis and electro-catalysis

Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End,

Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

01763262333

CHARACTERISATION OF BATTERY COMPONENTS

The

porous

nature

of

electrode

components,

finished

electrode

architectures

and

separator

materials

is

critical

to

the

performance

optimisation

of

battery

systems.

Pore

volume

and

pore

size

distribution

have

profound

effects

on

energy

density,

electrolyte

transport

characteristics,

electrode

conductivity,

cycling

lifetime

&

degradation

and

availability

of

active

sites

for

electrochemical

reaction.

When

electrode

materials

contain

active

metals

doped

to

a

substrate,

their

dispersion

and

surface

area

have

a

primary

influence

over

battery

performance and efficiency.

The

understanding

of

the

porosity

of

battery

components

is,

therefore,

necessary

at

all

stages

of

battery

development:

materials

selection,

production

and

failure

analysis.

Measuring

the

dispersion

and

surface

area

of

active

metals

by

chemisorption

is

a

valuable

tool

for

the

understanding and optimisation of battery systems.

Key Benefits:

•

Pore volume and pore size distribution characterisation

•

Tortuosity measurement for studying pore networks

•

Characterisation of component material porosity

•

Characterisation of finished electrode porosity

•

Measurement of active metal properties via chemisorption

•

Establishing process control settings for electrode manufacture

•

Characterisation of separator porosity

•

Assistance with data interpretation

•

Expansive data presentation and comparative overlay options

•

Highly experienced in catalysis and electro-catalysis

Our

gas

adsorption

and

mercury

porosimetry

techniques

are

applicable

to

the

investigation

of

component

materials,

such

as

carbons,

graphites

and

active

cathode

materials.

An

understanding

of

the

porous

nature

of

these

is

vital

for

determining

packing

characteristics,

electrode

conductivity

and

electrochemical

activity.

Careful

selection

of

raw

materials

having

optimum

porosity

is

often

required

so

that

a

desired

balance

between

efficiency

and

cycling

lifetime is achieved.

The

porous

nature

of

finished

electrodes

is

likely

to

be

different

from

the

components

materials

due

to

processing.

However,

this

porosity

exerts

profound

influence

over

electrolyte

transport,

conductivity,

availability

of

active

reaction

sites,

mechanical

stress,

charge

/

discharge

characteristics

and

cycling

lifetime.

Mercury

porosimetry

is

ideally

suited

to

the

characterisation

of

finished

electrodes

and

can

be

extended

to

measure

the

tortuosity

of

a

pore

network,

providing

vital

information relating to many of these performance measures.

Mercury

porosimetry

is

also

applicable

to

the

determination

of

the

porous

structure

of

separator

materials,

where

a

tight

distribution

of

pores of a certain size is demanded for efficient transfer properties.

For

active

metal

impregnated

systems,

the

active

metal

surface

area

and

dispersion

can

be

measured

accurately

by

chemisorption

(chemical

adsorption).

MCA

Services

offers

a

range

of

adsorptive

options,

CO

and

H

2

being

commonly

applied,

and

two

techniques:

static

and

dynamic

(pulse)

chemisorption.

A

wide

range

of

active

metals and metal loading s can, therefore, be characterised.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

porosity

with

the

experience

and

expertise

to

actively

assist

with

interpretation

of

results.

We

have

extensive

experience

in

the

characterisation

of

carbons

and

graphites

as

well

as

research

and

development

of

Li-ion

battery

technology.

Our

ongoing

in-house

research

has

focused

on

battery

and

super-capacitor

applications: a field in which we have journal publications.

Key Techniques:·

BET Surface Area - by nitrogen or krypton adsorption

Micropore Analysis - pore size, area and volume distribution

Gas Adsorption - pore size, area and volume distribution in the

mesopore range

Mercury Porosimetry - for pore size, pore volume & pore area

distribution

Mercury Porosimetry - for cavity to throat size evaluation

Permeability and Tortuosity measurement via Mercury Porosimetry &

Pycnometry

Chemisorption by a range of gases for analysis of catalysts

Density measurement - absolute density, bulk density & skeletal

density

Total Pore Volume and Solid Fraction measurement